Pipes and vents

WIP

General Information

All gases can flow through the various pipes found in the game. Gas will always attempt to flow from higher pressure to lower pressure. If a gas is not in a pipe, canister, or tank, it will be in the atmosphere and will interact with other objects.

Gas will always try to even out the pressure. For example, if a empty canister is connected to a pipe pressurized at 4500kpa, the canister will also only be pressurized to 4500kpa. If a canister pressurized at 9000kpa is connected to the same pipe, gas will flow out of the canister until a even pressure is acquired.

If pressurized pipes get unwrenched they will dump all of their contents into the surrounding atmosphere and will, depending on the pressure level, violently blow the wrench user away. You will know if you are unwrenching a pressurized pipe if you get the message stating "A gush of air blows in your face... Maybe you should reconsider?" It is good practice to always use your gas analyzer on every pipe before unwrenching to ensure it is depressurized.

All pipes can be unwrenched to disconnect them from others. By using a welder on a unwrenched pipe segment you can deconstruct it into steel.

A broken or unconnected segment of pipe WILL NOT allow gas to pass through. Do not worry about all your gas escaping out of a broken or unconnected pipe segment.

Most pumps, mixers, and filters do not require power to function. Only air vents and scrubbers require power. You can shift-click on a segment to examine it to see if it is powered.

Pipes

Allows gas to flow freely. Comes in four shapes. Straight, Elbow, 3-way-juntion, 4-way-junction.

Pumps

Pumps gas to the other side based on the set pressure. Blocks gas from passing through if toggled off. Comes in two varities:

Standard gas pump. Pumps gas along based on internal and external pressure. Has a maximum throughput of 4.5 Mpa. Mostly used to act as a valve to allow/disallow gas to flow from one pipe to another. Works very well in high pressure pipes but looses effectiveness when the pressure is lower. Regular gas pumps are more effective in lower pressure systems but will lose efficiency as the volume of gas rises.

At lower pressures a gas pump is generally a better option at moving gas.

Volumetric pump. Pumps gas along based of internal and external mole amount. Has a maximum throughput of 200 L/s. Acts exactly like a gas pump but works off of mole amount instead of pressure. Can move about twice as much gas compared to a regular gas pump if conditions are right.

For extremely high pressure pipes a volumetric pump is generally a better option at moving gas.

In certain cases volumetric pumps are also better if you are using huge quantities of gas.

Manual Valves

Acts like a switch that either allows gas to flow through, or prevents it from flowing through. Can be toggled on and off.

| Image | Name | Description |

|---|---|---|

| Manual valve open | A green light is open. | |

|

Manual valve closed | A red light is closed. |

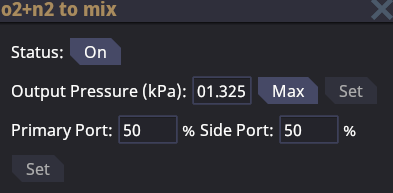

Gas Mixer

A gas mixer is a fancy version of the gas pump. It allows you to combine the gas flow of two different pipes and mix them into a single pipe. The gas mixer will combine the contents of two different pipes and will give you the option of setting the percentage of throughput you want on each of the input pipes. The primary port will be parallel with the output while the side port will be perpendicular.

Gas mixers are essential for distro as the station's atmosphere is 20% oxygen and 80% nitrogen. Gas mixers are also used for the combination of two different gases to create a new gas such as a common burn-mix.

If the gas mixer is toggled off then it will not allow any gas to flow through.

If both inputs are set to receive gas then both inputs must have gas flowing through them for the pump to work. For example, if the mixer is set to mix gas at a 80 to 20 ratio and the input pipe at 20% has no gas then the mixer will not allow the input pipe with 80% gas to flow through and vice versa.

Gas Filter

Gas filters are another special type of gas pump. Gas filters are primarily used to extract a specific individual type gas from a pipe. They function similarly to the gas mixer, except they have one inlet port and two output ports. When gas flows through a mixer the selected gas to be filtered out will exit the perpendicular outlet port while all other gases will continue to flow down the parallel outlet port. If you wish to filter out more than one gas you will need to set up gas filters in series for each specific gas.

Gas filters are used to extract each individual gas from the waste loop. This ensures that only one type of gas is present in each specific gas holding tank. Gas filters are essential when you are trying to target and isolate a specific gas.

Gas filters do not require both outputs to be connected to function if there is no gas selected to filter or the filtered gas is not present. In this case the filter will act as a simple straight pipe segment. However, The filter will not allow gas to flow if the selected gas is present and there is no pipe connected to the perpendicular filter port.

Vents

Gas vents come in three varieties: Standard, Dual-port, and Passive.

All gas vents are solely used to move gas from pipes into the surrounding atmosphere. Gas vents are commonly used in conjunction with the distro loop to distribute breathable air to the station. Gas vents and the distro system are responsible for replenishing the atmosphere on the station.

A standard air vent will only allow a maximum pressure of 101.3 kPa to flow. If the external pressure is higher than the limit, no gas will flow out of the vent. Requires power to function.

A dual-port air vent is exactly like a standard air vent but it has two inlet connection ports.

A passive air vent does not require power and will allow any pressure to flow in both directions depending on the internal and external pressures. If the internal, or pipe pressure, is higher than the external, or outside atmosphere, Gas will flow out. The opposite is true if the external pressure is higher than the internal pressure. Passive air vents are mostly used in the mix tank and Supermatter chamber where very high pressures are needed.

Air Scrubber

Air scrubbers slowly suck gas out of the surrounding atmosphere and can be found spread around the station. Mostly used in the waste loop, air scrubbers will syphon gas out of the atmosphere and shunt it along the waste loop where the gas will then be recycled and filtered into the gas holding chambers. By default, scrubbers are set to scrub the surrounding air of all gases except oxygen and nitrogen. You can set them to siphon if you want to suck in all gasses, or you can configure them to scrub whichever gasses you like. To do so, note the scrubber name and go to the air alarm to modify the relevant scrubber. Note that siphoning can be a good way to decrease room pressure.

Air scrubbers must be powered and connected to an outlet port in order to function. A properly functioning air scrubber will be glowing blue.

Air Injector

Air injectors have one purpose. They simply exist to only allow gas to flow from a pressurized pipe into the surrounding atmosphere. This handy little tool is useful when you want to inject a gas into an area but not allow any backflow. usually used with a filter/injector combination to single out a specific gas and pump it into a holding chamber.

Air injectors have a maximum output pressure of 9000 kPa.

Pneumatic Valve

![]() Pneumatic valves have three ports: control, inlet, and outlet. Like manual valves, pneumatic valves permit bidirectional flow between the inlet and outlet, but only if the pressure at the control port is high enough.

Pneumatic valves have three ports: control, inlet, and outlet. Like manual valves, pneumatic valves permit bidirectional flow between the inlet and outlet, but only if the pressure at the control port is high enough.

To turn a pneumatic valve on, the control pressure must be at least 1 atm higher than the lowest pressure connected to the pneumatic valve, i.e. the lesser of the inlet and outlet pressures. The direction of flow between the inlet and outlet is from higher to lower pressure.

The flow rate limit of the pneumatic value is linear (proportional to control pressure) in a small region above the on threshold. It then saturates at 200 L/sec.

Design Examples

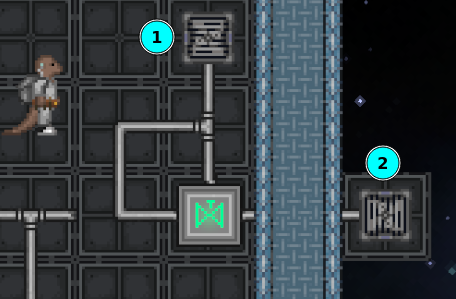

Pressure Relief Valve

This pressure relief system drains the air inside to space if the pressure exceeds 1 atm, which can be used to guard against accidental station overpressure events. A passive vent inside (1) is connected to the control and the inlet. Another passive vent in space (2) is connected to the outlet. Since the outlet pressure is 0 kPa, then the pneumatic valve will only be on if the inside pressure exceeds 1 atm. When that happens, air from inside is transferred into space until the inside pressure is equal to 1 atm.

Turing Completeness

Pneumatic valves make atmos turing-complete.

Connector Port

Connector ports are solely used to transfer gas from a pipe into a canister and vice versa. Wrench a canister on top of a connector port to connect them. A connected canister will allow gas to flow until the pressure evens out.

Canisters

Canisters are used to hold and transport gas. Drag a canister over to a connecter port and use a wrench to connect it. If the connecter port's internal pressure is higher than the canister pressure, gas will flow into the canister until the pressure evens out.

If the canister has a higher pressure gas will flow out until the pressure difference is even. Canisters can release gas in different ways depending on the situation. Gas will only flow out if the release valve is toggled open. If the release valve pressure is lower than the external pressure, no gas will flow out.

- If the canister is wrenched to a connector port, gas will flow into the connector port.

- If a oxygen tank is inserted into a canister, gas will flow into the oxygen tank.

- If the canister is not connected to anything, gas will flow out into the surrounding atmosphere.

Gas Miner

Gas miners create new gas from nothing and are currently used to make sure the station has an infinite amount of a specific gas. Gas Miners come in different types and create different types of gas. A oxygen miner will create oxygen gas while a plasma miner will create plasma gas. Gas Miners can be found in Atmospherics inside each gas holding chamber.